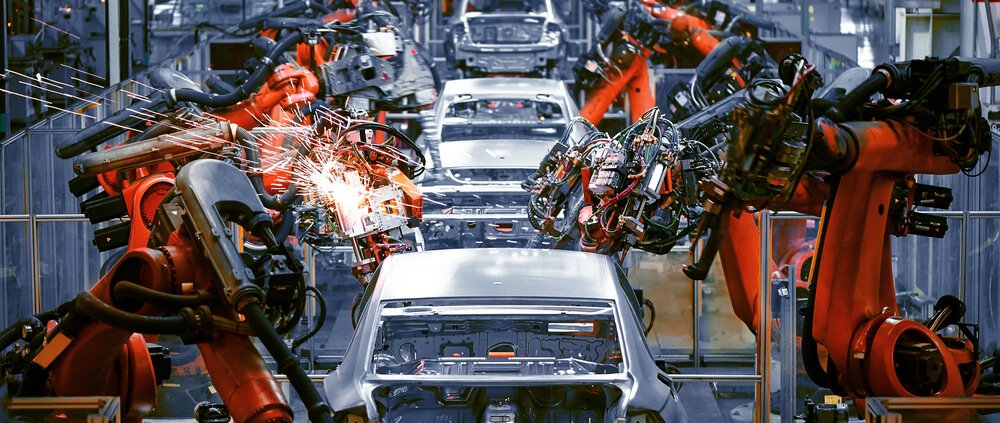

Robotics has become a key player in the automotive industry, a statement that can be made thanks to the advances that robotization in the industrial sector has generated over the years. It is expected that during 2021 there will be approximately 381 million industrial robots around the world. Mexico is not far behind, as it is ranked number 9 of the 15 countries with more industrial robot installations per year, according to the report World Robotics 2020, by the International Federation of Robotics (IFR).

Advantages of Robots in the Automotive Industry

- The profitability is one of the most compelling arguments for industrial robots. Robots will reduce production costs by eliminating those internal expenses to offset workers’ wages. Entrepreneurs predict that their profitability will increase as robots are introduced into manufacturing, or that they will be more financially mobile to invest in new products or technologies.

- Quality assurance is improved with the use of machines in production. Industrial robots will be able to ensure the consistency of manufactured products with mass production. The possibility of human error that assembly line workers may encounter will be eliminated.

- Optimized production efficiency means that the general manager can set the quantity and quality standards that robots must meet. Production quotas will not be compromised by low concentration, interruptions and employee injuries, among other things. The efficiency of production forecasts and supply levels will be improved by robots that can be programmed to operate at the optimal speed for a given plant.

- Restrict human labor in hazardous conditions, as manufacturing jobs often expose workers to greater physical risk than many other industries. Reducing the level of danger presented by workers in the workplace is attractive to managers in order to preserve the company’s reputation and minimize potential legal liabilities. High-risk industries such as manufacturing and mining, which suffer notorious disasters, are turning to robots for their ability to replace unskilled workers performing essential work in hazardous environments.

What do robots do in the automotive industry?

Industrial robots are successfully operating in various industries such as agriculture, food industry, and electronics. However, robotization in the automotive industry is the most efficient. What are these machines doing in this industry to make the demand so high?

The mentioned industries are where dynamic changes are occurring; such as new technologies, trends and orders. Modern automobiles could not be created today without the involvement of modern robots. They have many applications, which have been constantly progressing. Robots involved within the automotive industry can perform different activities, such as:

Paint jobs: Colors are of great importance in the automotive industry. People are looking to stand out by customizing their cars, so they are more often choosing eye-catching colors. The times when the showroom was filled with several copies of the same model in the same color, and the choice of a particular one was determined by a limit of models, are gone forever.

The easiest way to adapt to the market’s color requirements is by using painting robots. Then only the paint containers are replaced. There are many benefits: speed, precision, consistency in quality level, readiness for large-scale production. Finally, it is important to mention the protection of the health of people who could theoretically perform this work, since by robots performing this activity, it helps to preserve human health, by avoiding exposing people in a room full of chemicals and dust.

Transfer: Industrial robots are perfect where a lot of force is needed. Automotive is an industry where weight is most often expressed in tons, and this unit does not go hand in hand with the work of human hands.

Because of the heavy and large parts, industrial robots work well in handling them. Those with high load capacity move parts without any stress, and the chances of damage during the handling of these parts are unlikely.

Assembly: Automotive requires precision. Only industrial robots can provide the highest precision on a mass-production scale. This is another reason why they are a good choice for automotive manufacturers.

First, for robots, it doesn’t matter whether they assemble the first, the hundredth or the thousandth car. They will always retain the same high precision. Robots do not experience fatigue or a moment’s inattention. They are a good substitute for people where there is no room for error. Robots make far fewer, if any, mistakes.

Quality control

The robot is a master of repeatability. It always evaluates the same thing strictly. It will notice even the slightest deviation from the other controlled copies. In a word, it is the perfect candidate to keep control of something that must be perfect.

Moreover, it is easier for a robot to inspect an object the size of a car. It can use several of its arms to inspect all the parts while maintaining quality control. All this can be done in one place, using one robot and programming according to the specifications of the checklist.

The automotive world values the excellence of industrial robots. Perhaps that is why they are such popular machines in this industry. They have been working for many years and production has adapted to them to such an extent that we would no longer do without their help.

All the advantages we have shared make industrial robots extremely useful in the automotive industry. These devices are getting smarter every day and everything points to their technology developing even further.

In VYNMSA we are fully equipped to develop your Build To Suit project and accomplish the infrastructure requirements for the automotive sector. We also have around 20 inventory buildings ready for immediate occupancy, totaling 1.7 million square feet of space in the northeast and bajio region.

We are one of the leading industrial real estate developers in Mexico with nearly 30 years of experience helping companies establish operations in Mexico. Contact us and find out why VYNMSA can successfully develop your project.